توضیحات محصول:

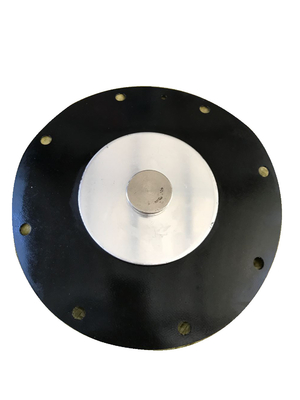

دیافراگم شیر برقی یک جزء حیاتی است که برای افزایش عملکرد و قابلیت اطمینان سیستمهای مختلف شیر برقی طراحی شده است. این دیافراگم که با دقت و دوام مهندسی شده است، با طیف گستردهای از کاربردها، از جمله سیستمهای شیر برقی تعلیق هوا و کویلهای شیر برقی هیدرولیک، سازگار است. ساختار مستحکم آن عملکرد بهینه را تضمین میکند و آن را به انتخابی ایدهآل برای صنایعی تبدیل میکند که راندمان بالا و عملکرد طولانیمدت را طلب میکنند.

یکی از ویژگیهای برجسته این دیافراگم شیر برقی، محدوده دمایی چشمگیر آن است که از -20 درجه سانتیگراد تا 80 درجه سانتیگراد متغیر است. این محدوده دمایی وسیع به دیافراگم اجازه میدهد تا در شرایط محیطی متنوع، چه در آب و هوای سرد و چه در محیطهای صنعتی گرمتر، به طور مداوم عمل کند. چنین تطبیقپذیری تضمین میکند که دیافراگم یکپارچگی و پاسخگویی خود را بدون به خطر انداختن راندمان کلی شیر برقی حفظ میکند.

این دیافراگم به طور خاص برای کار یکپارچه با انواع کویلهای برقی طراحی شده است و آن را به یک تطابق عالی برای سیستمهای شیر برقی که به کویلهای الکترومغناطیسی برای عملکرد متکی هستند، تبدیل میکند. این شامل کاربردهایی میشود که شامل کویلهای شیر برقی هیدرولیک است، جایی که کنترل دقیق جریان و فشار سیال ضروری است. با ادغام این دیافراگم، کاربران میتوانند انتظار عملکرد آببندی بهبود یافته و کاهش سایش را داشته باشند که برای حفظ طول عمر سیستمهای هیدرولیک بسیار مهم است.

مقاومت در برابر خوردگی یکی دیگر از ویژگیهای مهم این محصول است. دیافراگم که از مواد باکیفیت ساخته شده است، مقاومت بالایی در برابر خوردگی نشان میدهد و اطمینان حاصل میکند که میتواند در معرض مایعات مختلف و محیطهای عملیاتی سخت بدون تخریب قرار گیرد. این ویژگی به ویژه در کاربردهایی که شامل سیالات هیدرولیک و سیستمهای تعلیق هوا میشود، که در آن قرار گرفتن در معرض رطوبت، مواد شیمیایی و سایر عوامل خورنده رایج است، مهم است. مقاومت بالای در برابر خوردگی، عمر مفید دیافراگم را افزایش میدهد و دفعات تعمیر و تعویض را کاهش میدهد.

نصب به لطف نوع نصب پیچی، ساده و کاربرپسند است. این طراحی فرآیند نصب را ساده میکند و به تکنسینها اجازه میدهد تا دیافراگم را به سرعت و ایمن در مجموعه شیر برقی بدون نیاز به ابزارهای تخصصی یا روشهای پیچیده نصب کنند. نوع پیچی همچنین تناسب محکم و قابل اعتمادی را تضمین میکند که برای جلوگیری از نشت و حفظ یکپارچگی سیستم ضروری است.

این دیافراگم برای شیرهایی با اندازه دهانه 3/4 اینچ طراحی شده است و آن را برای انواع پیکربندیهای شیر برقی مناسب میکند. این اندازه دهانه استاندارد، سازگاری با بسیاری از سیستمهای موجود را تضمین میکند و امکان ادغام و جایگزینی آسان را فراهم میکند. چه در حال ارتقای یک شیر برقی تعلیق هوا یا نگهداری از یک کویل شیر برقی هیدرولیک باشید، این دیافراگم به طور یکپارچه جا میافتد و عملکرد و قابلیت اطمینان ثابتی را ارائه میدهد.

به طور خلاصه، دیافراگم شیر برقی ترکیبی از دوام، تطبیقپذیری و سهولت نصب را ارائه میدهد که برای پاسخگویی به نیازهای کاربردهای مدرن شیر برقی طراحی شده است. محدوده دمایی وسیع (-20 درجه سانتیگراد تا 80 درجه سانتیگراد)، مقاومت بالای در برابر خوردگی و سازگاری با انواع کویلهای برقی، آن را به یک جزء ضروری برای سیستمهای شیر برقی تعلیق هوا و کویلهای شیر برقی هیدرولیک تبدیل میکند. نصب پیچی و اندازه دهانه 3/4 اینچی، کاربردی بودن آن را بیشتر میکند و اطمینان حاصل میکند که عملکرد قابل اعتمادی را در تنظیمات مختلف صنعتی ارائه میدهد.

این دیافراگم شیر برقی را انتخاب کنید تا اطمینان حاصل کنید که سیستمهای شیر برقی شما به آرامی، کارآمد و با حداقل زمان خرابی کار میکنند. طراحی مستحکم و کیفیت مواد آن، طول عمر و عملکرد قابل اعتماد را تضمین میکند و به شما کمک میکند تا کنترل بهینه بر جریان و فشار سیال در کاربردهای حیاتی را حفظ کنید. چه با سیستمهای تعلیق هوا یا کویلهای شیر برقی هیدرولیک سروکار داشته باشید، این دیافراگم برای پاسخگویی به نیازهای شما با برتری و دقت مهندسی شده است.

ویژگیها:

-

نام محصول: دیافراگم شیر برقی

-

اصل کار: پایلوتدار

-

آببندی: آببندی خوب

-

جنس دیافراگم: لاستیک نیتریل

-

ضخامت: 1.5 میلیمتر

-

محدوده دما: -20 درجه سانتیگراد تا 80 درجه سانتیگراد

-

سازگار با کاربردهای شیر برقی فشار بالا

-

ایدهآل برای سیستمهای شیر برقی تعلیق هوا

-

مناسب برای استفاده با کویل شیر برقی هیدرولیک

پارامترهای فنی:

|

آببندی

|

آببندی خوب

|

|

محدوده فشار

|

0 تا 10 بار

|

|

مناسب

|

شیر پنوماتیک شیر برقی ASCO

|

|

اصل کار

|

پایلوتدار

|

|

فشار کاری

|

0-10 بار

|

|

اندازه دهانه

|

3/4 اینچ

|

|

جنس

|

NBR (لاستیک نیتریل بوتادین)

|

|

فشار

|

0-10 بار

|

|

مقاومت در برابر خوردگی

|

مقاومت بالا در برابر خوردگی

|

|

نوع نصب

|

پیچی

|

کاربردها:

دیافراگم شیر برقی HONGUM یک جزء همه کاره و قابل اعتماد است که برای طیف گستردهای از کاربردها در صنایع مختلف طراحی شده است. ساختار مستحکم و مهندسی دقیق آن، آن را برای استفاده در سیستمهایی که نیاز به کنترل کارآمد جریان سیال تحت شرایط فشار و دمای مختلف دارند، ایدهآل میکند. با محدوده دمایی -20 درجه سانتیگراد تا 80 درجه سانتیگراد، این دیافراگم عملکرد پایداری را حتی در محیطهایی با شرایط حرارتی متغیر تضمین میکند.

یکی از موارد کاربرد اصلی دیافراگم شیر برقی HONGUM در سیستمهای شیر برقی فشار بالا است. این شیرها در صنایعی مانند تولید، خودروسازی و اتوماسیون صنعتی ضروری هستند، جایی که کنترل جریان گازها یا مایعات تحت فشار تا 10 بار حیاتی است. اصل کار پایلوتدار دیافراگم، عملکرد روان و کارآمد شیر را امکانپذیر میکند، سایش را به حداقل میرساند و طول عمر کل مجموعه شیر را افزایش میدهد.

در بخش خودرو، دیافراگم HONGUM کاملاً برای کاربردهای شیر برقی تعلیق هوا مناسب است. سیستمهای تعلیق هوا برای ارائه یک سواری راحت و افزایش پایداری خودرو به کنترل دقیق فشار هوا متکی هستند. سازگاری دیافراگم با کویلهای برقی، پاسخ سریع و دقیق شیر را تضمین میکند که برای حفظ عملکرد بهینه تعلیق بسیار مهم است. نوع نصب پیچی آن نیز جایگزینی و نگهداری آسان را تسهیل میکند و زمان خرابی را برای سرویس خودرو کاهش میدهد.

علاوه بر این، دیافراگم شیر برقی HONGUM با کویلهای شیر برقی هیدرولیک مطابقت خوبی دارد و آن را به انتخابی عالی برای سیستمهای هیدرولیک که نیاز به کنترل سیال قابل اعتماد دارند، تبدیل میکند. ماشینآلات هیدرولیک در صنایع ساختمانی، کشاورزی و تجهیزات سنگین از توانایی دیافراگم برای مقاومت در برابر فشارهای بین 0 تا 10 بار در حالی که عملکرد ثابتی را حفظ میکند، بهره میبرند. ادغام کویل برقی، عملکرد الکترومغناطیسی دقیقی را تضمین میکند و امکان کنترل کارآمد جریان سیال هیدرولیک در سیستمهای پیچیده را فراهم میکند.

به طور کلی، دیافراگم شیر برقی HONGUM در سناریوهایی که نیاز به دوام، دقت و سازگاری دارند، برتری دارد. چه در شیرهای برقی فشار بالا، شیرهای برقی تعلیق هوا یا کویلهای شیر برقی هیدرولیک نصب شود، این دیافراگم عملکرد قابل اعتمادی را ارائه میدهد. اصل کار پایلوتدار آن همراه با تحمل دمای وسیع و نصب آسان پیچی، آن را به یک جزء ضروری برای سیستمهای کنترل سیال مدرن تبدیل میکند.

پشتیبانی و خدمات:

محصول دیافراگم شیر برقی ما با پشتیبانی و خدمات فنی جامع پشتیبانی میشود تا عملکرد و قابلیت اطمینان بهینه را تضمین کند. تیم متخصصان ما برای کمک به راهنمایی نصب، عیبیابی و روشهای نگهداری در دسترس هستند. ما اسناد فنی دقیقی از جمله مشخصات، دفترچههای راهنما و دستورالعملهای تعمیر را ارائه میدهیم تا به شما در به حداکثر رساندن طول عمر و راندمان دیافراگم کمک کنیم.

ما جلسات آموزشی و کارگاههایی را برای کارکنان فنی شما ارائه میدهیم تا درک آنها از ویژگیهای محصول و تکنیکهای جابجایی مناسب را افزایش دهیم. علاوه بر این، ما خدمات گارانتی و قطعات جایگزین سریع را برای به حداقل رساندن زمان خرابی در عملیات شما ارائه میدهیم.

برای کاربردهای پیچیده، تیم پشتیبانی مهندسی ما میتواند با شما همکاری کند تا راهحلهایی را سفارشی کند که نیازهای خاص شما را برآورده کند. تعهد ما ارائه خدمات استثنایی و اطمینان از عملکرد قابل اعتماد دیافراگم شیر برقی شما در همه شرایط عملیاتی است.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!